News

Fish Feed Extruder for Fish Farmers to Produce Quality Feed

Fish feed pellets are the popular feed in market fish

How much is a fish feed pellet machine in Nigeria

Fish feed pellet shop is the pelleting machine that directly

Reasonably Priced Fish Feed Pellet Machine in Nigeria

Lima is a manufacturer specialized in producing fish feed extruders.

Tips for Maintenance of Floating Fish Feed Pelleting Machine

The feed pelleting machine is the main equipment in the production process of each feed factory, and it can also be said to be the heart of the feed pellet production line. The correct use of the floating fish feed extruder directly affects the economic benefits of the feed pellet. Therefore, how to properly use and maintain the floating fish feed extruder is a major issue for feed factories to improve production efficiency.

How the raw material modulation affects the feed pellet quality?

The conditioning of feed production generally refers to the powder stage before the pelletizing and puffing process, all the additions and changes between all materials entering the mixer and entering the ring cavity of the pelletizer. Traditionally, we will add steam in the conditioning stage. Of course, we can also use some liquid conditioning solutions. These operation steps can be added during the mixing process.

The superiority of extruder machines in aquatic feed production

Using the extruding equipment to process aquatic feed has the following advantages: It can produce a wide variety of products; Improve feed conversion rate; Improve the stability of feed in water; Easy to control the feed density; The mechanical properties of the finished feed are good. The lowest cost formula can be used to reduce the feed production cost; The feed is more hygienic.

Advantages of fish farming business in Nigeria

Nigeria has an advantageous geographical location and huge domestic demand for fish products, which is very suitable for the fish farming industry. At present, the Nigerian aquaculture industry is developing rapidly, but how to accurately grasp the opportunity to start farming, you need to understand the advantages of Nigerian aquaculture.

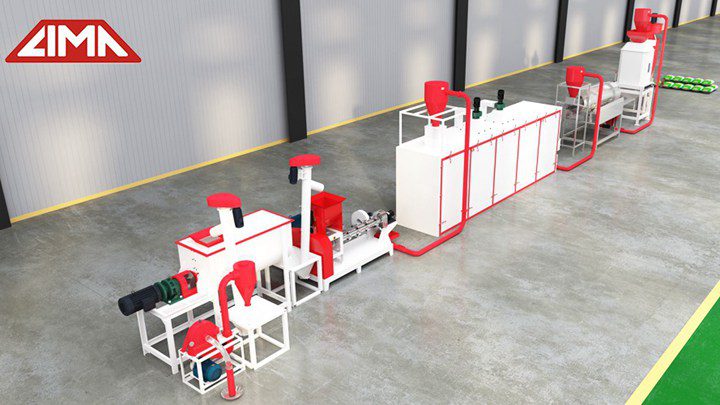

Machine included in an automatic floating fish feed production line

The automatic floating fish pellet production line is generally used in some large-scale production lines, which can effectively improve production efficiency, reduce production costs, and stabilize and improve product quality. The fully automatic floating fish pellet production line can effectively help the factory to realize the modernization of production and has good economic benefits.

How to make the floating fish feed pellets?

Floating extruded fish feed has the advantages of convenient management, high nutritional value, good stability, and less water pollution. If you want to produce high-quality extruded feed, you need not only a high-quality fish pellet machine but also advanced floating fish feed processing technology for support.

Guide about Catfish Farming in Nigeria

The demand for catfish in Nigeria is increasing at an annual rate of 10%, and all catfish cultured in Nigeria will eventually be digested by the local market. Nigeria has abundant annual rainfall and developed surface water systems, and most areas have the ability to carry out aquaculture. Basic conditions, catfish farming in Nigeria has now become a very effective and profitable project.

Tips about preventing fish diseases during fish farming

Fish are susceptible to disease like any other pets and when it comes to fish diseases, the keyword is prevention. Then how to prevent fish diseases during fish farming? In this post, I’m going to share more on fish diseases and what you can do now to prevent your fish from infecting any diseases.

Advantages and processing technology of floating feed

Extruded aquatic feed is a high-quality and environmentally friendly feed with low pollution, less waste, high efficiency, and a high conversion rate. The selection of floating fish feed is an important method to produce high-quality and safe animal products and ensure human health, and it is also the trend for the future development of the feed industry.

Chicken feeding and management methods

Rural loose chicken management technology has common characteristics with other breeding methods, the main stage of chicken death is 0~30 days old, due to the influence of temperature, environment, feeding, and other factors, plus human factors, the morbidity, and mortality are higher, let’s take a look at the rural loose chicken technology!

Tips for fish farming in ponds

The most common mode of fish farming is pond farming, but the management of fish farming in ponds is not simple. There are many problems such as the prevention of diseases, the aging of pond water quality, and the inconvenience of irrigation and drainage. So what are the methods and techniques of pond farming? Lima Machinery summarized seven points for customers’ reference

Scientific feeding of grass carp

In the process of grass carp breeding, the cost of feed can account for 70%-80% of the whole. The quality of the feed affects the quality and quality of the fish. To raise the fish, the scientific feeding and management of the feed are very important. In fish ponds for cultivating grass carp, water quality, bottom quality, feed, seed, animal protection use, and external facilities are all key factors that affect the success or failure of aquaculture. Among them, feed feeding is closely related to water quality and sediment quality.